International Paper Bag Plant: OEM Exporter of Eco-Friendly Packaging Solutions

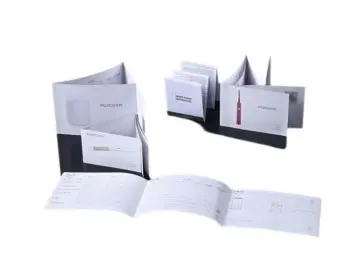

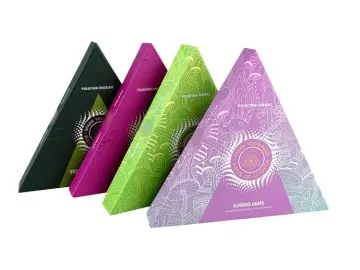

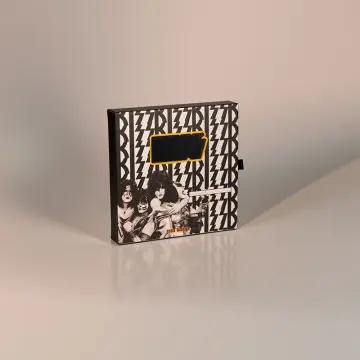

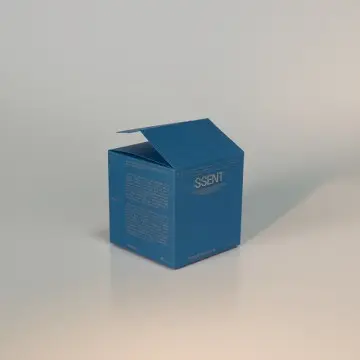

As a premier OEM and manufacturer in the packaging industry, we specialize in high-quality International Paper Bag Plants. Our advanced factory is dedicated to producing eco-friendly and resilient paper bags designed to fulfill your unique business requirements. With a focus on sustainability and innovation, our products adhere to global standards while catering to a variety of sectors. Partnering with us means collaborating with a dependable supplier who understands market specifics. Our committed team is eager to help you customize designs, sizes, and materials, ensuring our paper bags elevate your brand’s visibility and distinguish it on the shelves. Whether you're a small enterprise or a large corporation, our International Paper Bag Plant provides the flexibility and quality you need. Together, we can create impactful Packaging Solutions that propel your business forward!

Best Practices For International Paper Bag Plant Pioneers in the Field From Concept to Delivery

As the demand for sustainable Packaging Solutions grows globally, the international paper bag plant sector presents unique opportunities for entrepreneurs and businesses alike. From the initial concept stage to delivery, there are best practices that can streamline operations and ensure success in a competitive market. First and foremost, investing in advanced technology is critical. State-of-the-art equipment boosts efficiency, reduces waste, and enhances product quality—essential factors that resonate well with eco-conscious consumers. Moreover, a skilled workforce plays a pivotal role in the success of paper bag production. Continuous training and development can empower employees to leverage the latest techniques in packaging design and production, leading to innovative solutions that cater to diverse customer needs. Collaboration across departments—from design to logistics—ensures that the entire lifecycle of product development is seamless, allowing businesses to respond swiftly to market demands. Finally, establishing strong relationships with suppliers and distributors enhances the supply chain, ensuring timely delivery and consistent quality. Transparency and communication are key, facilitating a responsive approach to customer inquiries and shifts in demand. By implementing these best practices, pioneers in the paper bag industry can navigate challenges effectively and position themselves as leaders in sustainability and innovation in the global marketplace.

Best Practices For International Paper Bag Plant Pioneers in the Field From Concept to Delivery

| Best Practice | Description | Implementation Steps | Expected Outcome |

|---|---|---|---|

| Sustainable Sourcing | Utilize eco-friendly materials to minimize environmental impact. | 1. Identify certified suppliers. 2. Audit material lifecycle. 3. Partner with organizations for sustainability. | Reduced carbon footprint and enhanced brand reputation. |

| Automation in Production | Implement machinery to streamline bag manufacturing processes. | 1. Assess current production line. 2. Invest in automation technology. 3. Train staff on new machinery. | Increased efficiency and lower production costs. |

| Quality Control Measures | Ensure the quality of paper bags from production to delivery. | 1. Establish quality benchmarks. 2. Conduct regular inspections. 3. Utilize feedback loops for continuous improvement. | Higher customer satisfaction and reduced returns. |

| Effective Supply Chain Management | Optimize logistics and inventory for timely delivery. | 1. Analyze current supply chain processes. 2. Implement inventory management software. 3. Collaborate with logistics partners. | Improved delivery times and reduced shipping costs. |

| Regulatory Compliance | Ensure adherence to international manufacturing and environmental regulations. | 1. Stay updated on regulations. 2. Designate a compliance officer. 3. Conduct regular compliance audits. | Minimized legal risks and enhanced market access. |

Top-Rated International Paper Bag Plant Manufacturers You Can Rely On Products

I

Isaac Price

High-quality purchase! Their commitment to excellent customer service is commendable.

18 August 2025

M

Michael Lee

This item exceeded my expectations in terms of durability. The after-sales team was very professional and helped me resolve a minor issue swiftly.

01 August 2025

M

Mark Walker

Excellent product quality! The after-sales team demonstrated immense professionalism while dealing with my queries, making the entire experience pleasant.

17 July 2025

R

Rachel Moore

I love this product! The quality is fantastic, and the after-sales service team was incredibly professional and helpful throughout.

04 July 2025

J

Jessica Taylor

The product quality truly speaks for itself. The after-sales service staff were not only professional but also very friendly, making the entire process smooth.

18 August 2025

M

Michael Lewis

High-quality product! After-sales service was prompt and showed a deep understanding of customer needs.

26 June 2025