High-Quality Custom Paper Box Making Machines for Exporters – Boost Your Production

Scaling my packaging business has been transformed by the **Paper Box Making Machine**. This high-quality machine is engineered for optimal efficiency, enabling me to produce a range of paper boxes with accuracy and simplicity. Its advanced technology ensures that I maintain a competitive edge in the marketplace. Collaborating with trusted manufacturers and exporters such as Xinjinming (Shanghai) Packaging Technology Co., Ltd. gives me confidence in the machine's durability and performance. I value how this equipment enhances the production process, minimizes waste, and increases profitability. With features that cater to varied packaging requirements, it supports my business growth while meeting the demand for quality products. Investing in this Paper Box Making Machine represents a commitment to excellence in my offerings. Elevating my Packaging Solutions can lead to remarkable business improvement.

10 tips Paper Box Making Machine Now Trending Exceeds Industry Benchmarks

In the rapidly evolving packaging industry, the demand for efficient and innovative solutions is greater than ever. Among these solutions, paper Box Making Machines are gaining significant traction and have become a vital asset for businesses aiming to enhance productivity and reduce costs. These machines are now setting new industry benchmarks with advancements in technology that streamline the entire manufacturing process. From intuitive design interfaces to automated production capabilities, manufacturers are witnessing noticeable increases in output while maintaining superior product quality. The latest trends highlight several essential features that can help increase production efficiency and reduce waste. For instance, many contemporary machines integrate real-time monitoring systems, allowing for immediate adjustments during the production cycle. This feature not only ensures high-quality fabrication but also minimizes the potential for errors, significantly lowering overhead costs. Additionally, eco-friendly production processes are becoming prevalent, appealing to environmentally conscious consumers and businesses alike. Adopting sustainable practices not only meets regulatory requirements but also enhances brand reputation and customer loyalty. For global buyers looking to stay ahead in the competitive packaging landscape, investing in state-of-the-art paper Box Making Machines is crucial. Choosing advanced machinery that offers flexibility in design options and efficient materials usage can lead to remarkable improvements in profitability. As the industry continues to adapt to changing consumer demands and technological advancements, integrating these innovative solutions will help businesses thrive and maintain a competitive edge in the market.

10 tips Paper Box Making Machine Now Trending Exceeds Industry Benchmarks

| Tip Number | Tip Description | Industry Benchmark | Current Trend |

|---|---|---|---|

| 1 | Optimize Machine Speed | 300 boxes/hour | 350 boxes/hour |

| 2 | Use Eco-Friendly Materials | Standard paper | Recycled paper |

| 3 | Implement Automation | Manual handling | Fully automated processes |

| 4 | Regular Maintenance | Quarterly checks | Monthly checks |

| 5 | Train Operators | Basic training | Advanced proficiency |

| 6 | Energy Efficiency | Standard models | Energy-saving designs |

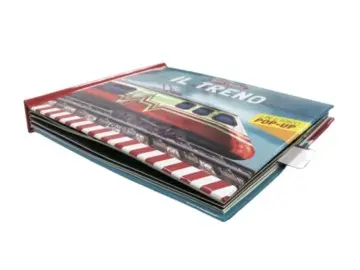

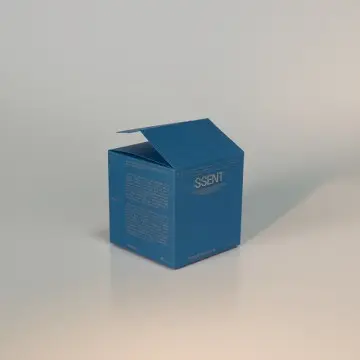

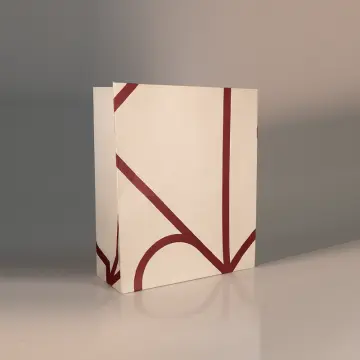

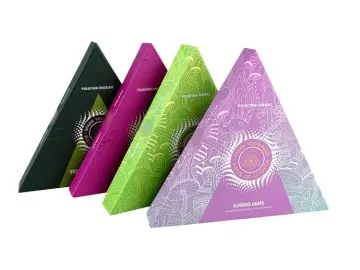

| 7 | Increase Box Customization | Limited options | Wide range of designs |

| 8 | Invest in Technology | Basic software | Advanced CAD systems |

| 9 | Enhance Quality Control | Infrequent checks | Continuous monitoring |

| 10 | Expand Market Reach | Local markets | Global distribution |

Key Steps to Choosing Paper Box Making Machine Delivers Unmatched Quality Exceeds Industry Benchmarks

A

Alexander Baker

Very satisfied with my purchase. The customer service representatives are knowledgeable and courteous.

26 July 2025

L

Lillian Bailey

This item surpassed my expectations. Their customer support is truly exceptional.

23 July 2025

J

Jessica Martinez

Fantastic quality! What impressed me even more was the knowledgeable after-sales team—they went above and beyond to ensure my satisfaction.

01 July 2025

A

Anthony Hill

I am beyond impressed! The quality of this product is exceptional, and the customer service was remarkably professional and efficient.

05 August 2025

N

Nicole Adams

Exceptional quality and great design! The after-sales support team was approachable and very knowledgeable. Highly recommend!

09 July 2025

M

Michael Brown

Remarkable quality and durability! The after-sales service provided was outstanding; they act with professionalism and dedication.

23 June 2025